Peiman Sarhani

Mechanical Engeering

Itally - padova

Expertise : Machinery & Automotive Designer & Agriculter Design

About me

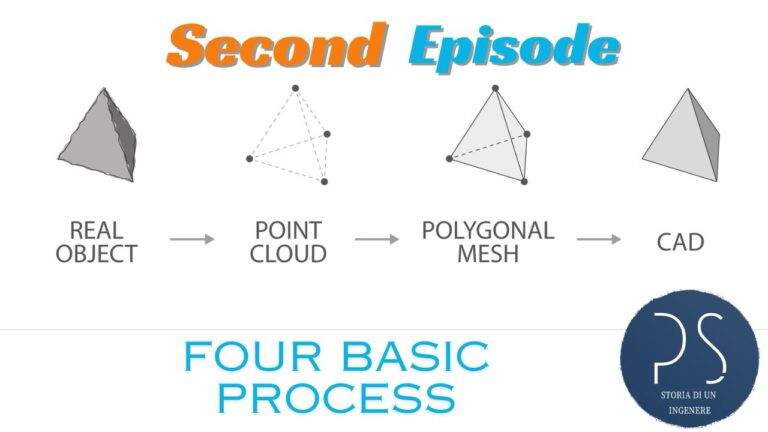

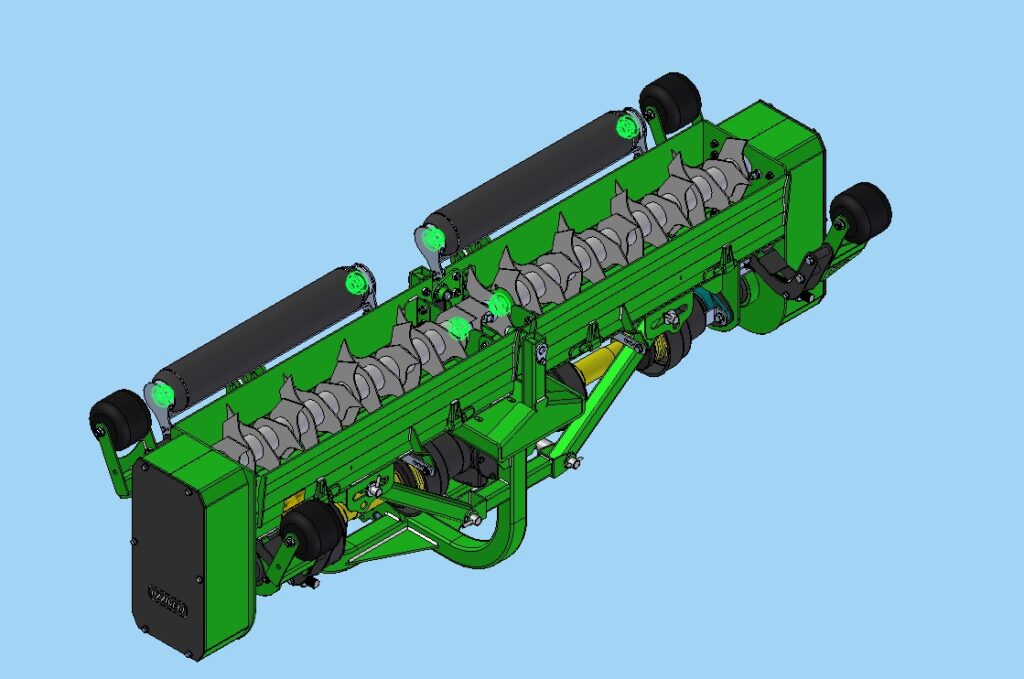

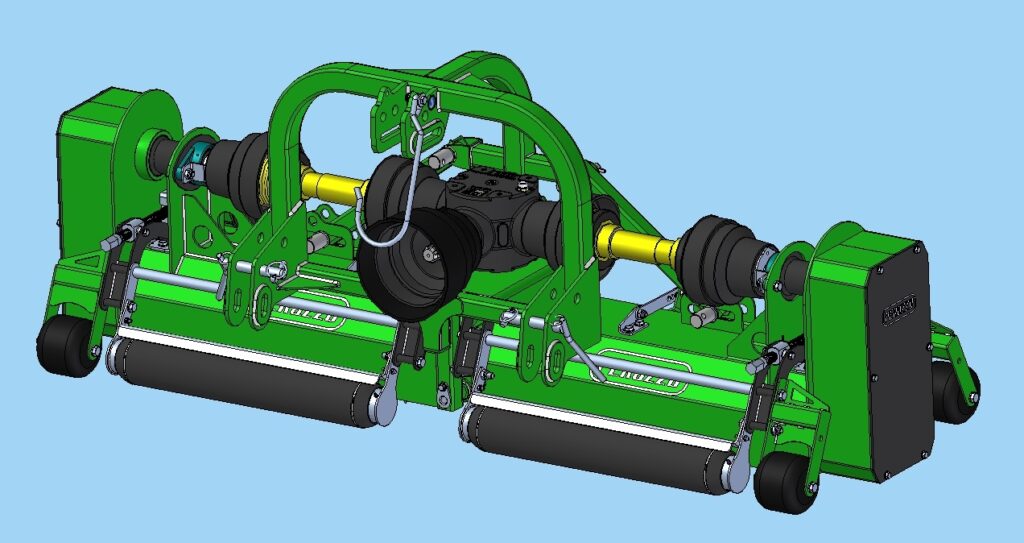

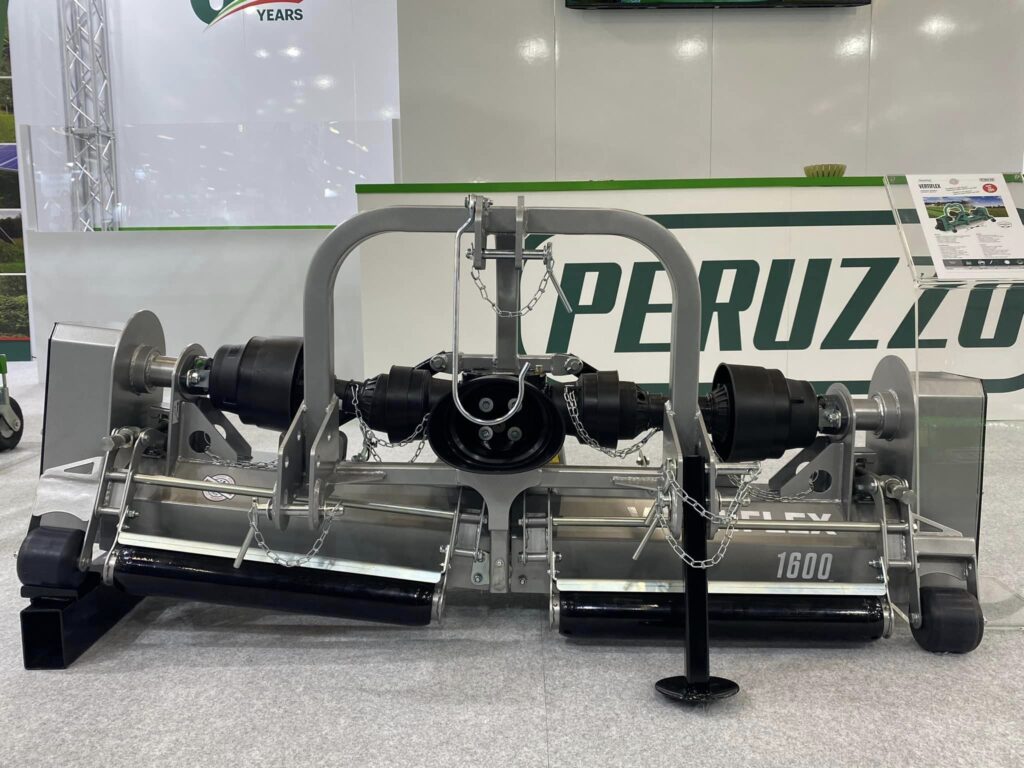

I am a Design and Manufacturing Engineer specializing in agricultural machinery and automotive design. With expertise in mechanical design, I use advanced tools like Solid Edge, SolidWorks, and AutoCAD to create high-performance systems. I am skilled in reverse engineering, 3D scanning, and CAD modeling, ensuring precision in all my projects. I focus on designing, analyzing, and optimizing mechanical systems, collaborating with multidisciplinary teams to improve product efficiency and sustainability. My goal is to develop reliable solutions through prototypes and material analysis.

Experience

agriculture Design

2024 AGU- 2024 NOV

As a valued member of the mechanical design team at Ingenium Pro, an esteemed engineering design company focusing on diverse industrial sectors, I specialize in machinery design.

Utilizing Cero and SolidWorks PDM software, I deliver comprehensive design solutions aligned with customer needs across various industries, including automation, scientific research (UHV machinery), winches, roller conveyors, traveling lifts, presses, industrial production lines, and high-pressure components.

Wood CNC Machine

·Led the design efforts for a Wood CNC Machine project, ensuring precision and efficiency in the manufacturing process.

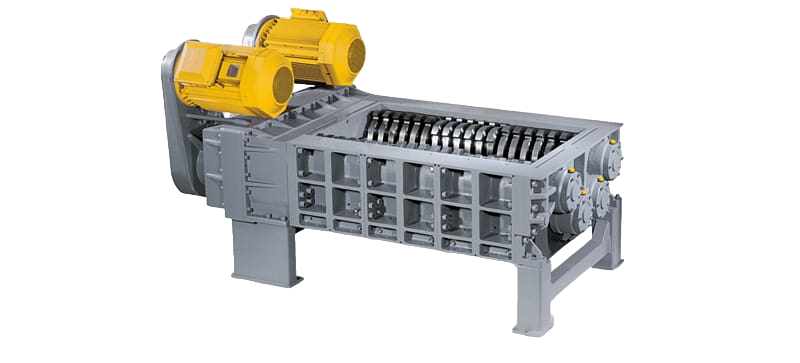

Shredded Two Shaft Machine

Fully designed and specified a two-shaft shredding machine, overseeing the manufacturing process from conception to completion.

Tubing and Electrical Routing

Played a pivotal role in the design of tubing and electrical routing for a unique machine at a private company, contributing to its overall functionality and reliability.

Skills:

Cero : Proficient in Drawing, Explode View, Design, and Material Feasibility.

SolidWorks : Expertise in routing and piping systems, seamlessly integrating with the PDM platform.

Achievements:

My experiences underscore my expertise in machinery design, showcasing a strong command of industry-leading software and successful contributions to diverse engineering projects.

Machinery Design Engineer

2023 AGU- 2024 march

Ingenium Pro

As a valued member of the mechanical design team at Ingenium Pro, an esteemed engineering design company specializing in diverse industrial sectors, I focus on machinery design. Leveraging my expertise in Cero and SolidWorks PDM, I deliver comprehensive design solutions tailored to customer needs across industries such as automation, scientific research (UHV machinery), winches, roller conveyors, traveling lifts, presses, industrial production lines, and high-pressure components.

Key Projects & Responsibilities

Wood CNC Machine

Led the design of a Wood CNC Machine, ensuring precision and efficiency in the manufacturing process.

Shredded Two Shaft Machine

Fully designed and specified a two-shaft shredding machine, overseeing the project from concept to completion.

Tubing and Electrical Routing

Played a pivotal role in designing tubing and electrical routing for a unique machine, ensuring its functionality and reliability.

Skills

Cero: Proficient in drawing, explode view, design, and material feasibility

SolidWorks: Expertise in routing and piping systems, with seamless integration into the PDM platform

Achievements

My experiences reflect my strong command of industry-leading software and successful contributions to a variety of engineering projects, particularly in machinery design. These achievements highlight my ability to drive innovation and efficiency in every project I undertake.

Senior Design Engineer

2022 MAY-2023 JUNE

Azin Electro IDEA

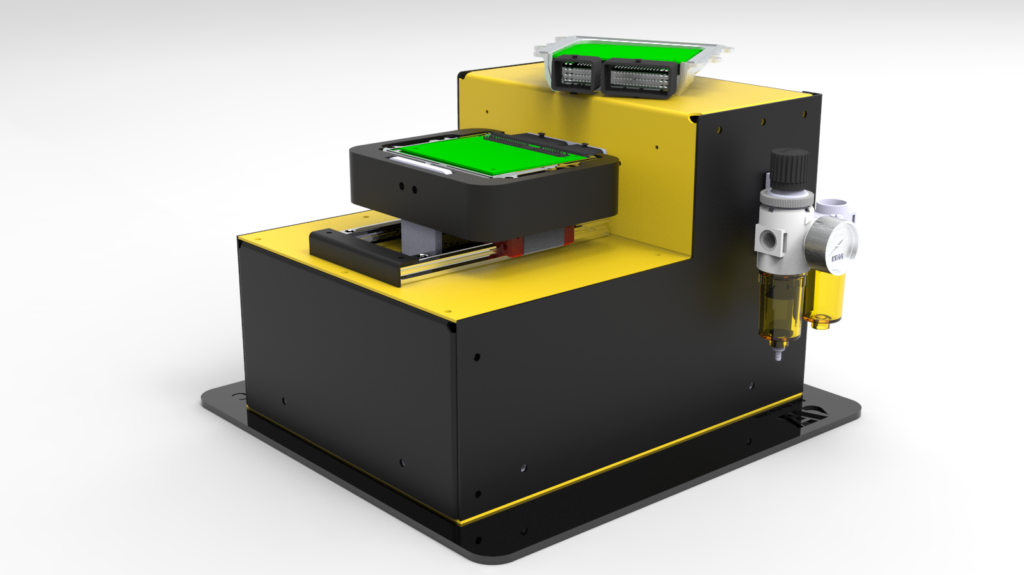

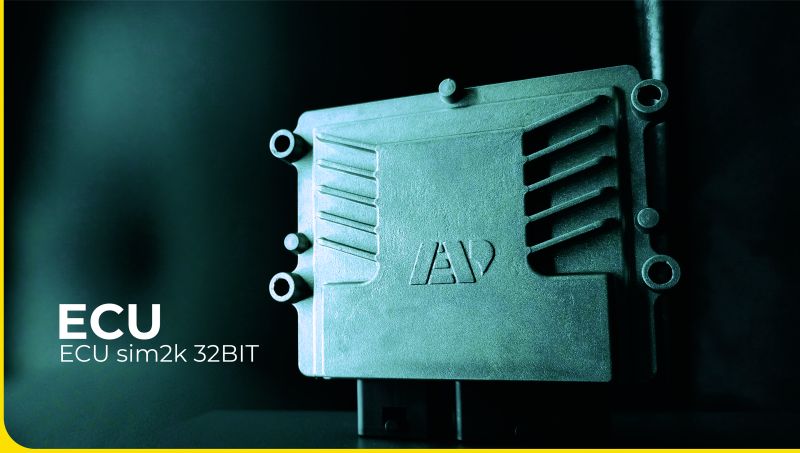

I led a team specializing in Jigs and Fixtures design for production lines, with a primary focus on creating an efficient frame design for the new Engine Control Unit (ECU) in two car models. I oversaw the ECU testing process, managing the construction of frames and fixtures with a pneumatic mechanism to support over 1,000 daily validations.

Key Achievements

Engineered an optimized ECU frame, improving both packaging and manufacturing efficiency.

Spearheaded the development of a jig and fixture for the Body Control Module (BCM), enhancing production line efficiency.

Utilized 3D printing and CNC manufacturing to produce over 50 spare parts, improving spare part availability and reducing downtime.

Skills

Jig and Fixture Design, Electronic Board Cover Design, Catia, 3D Printing

Responsibilities

Aligned mechanical designs in project planning meetings, collaborating with structural and architectural teams to resolve conflicts.

Conducted technical drawing reviews to ensure precision and adherence to industry standards.

Evaluated final product performance, reliability, and safety during testing.

Achievements

Successfully led critical projects, significantly improving production line efficiency.

Played a pivotal role in technological advancements, providing innovative solutions for ECU and BCM.

Mechanical Design Drafter and Developer

2019 JAN-2022 JAN

Jetco – Advanced Automotive Technology

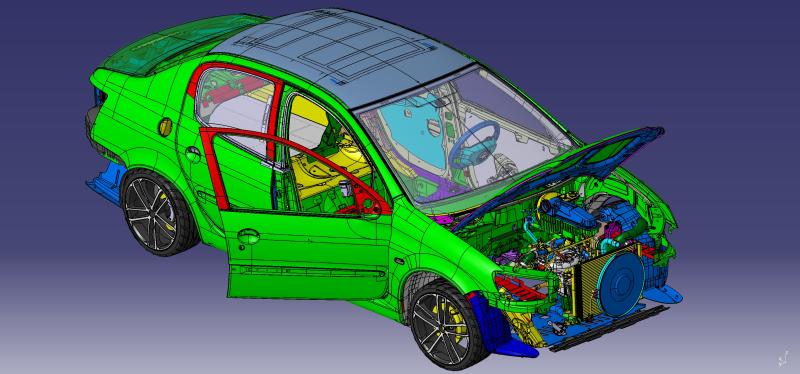

JETCO is a comprehensive automotive research and development company and a subsidiary of IKCO, one of the largest automotive groups in Iran. The company focuses on developing and designing car platforms and related technologies.

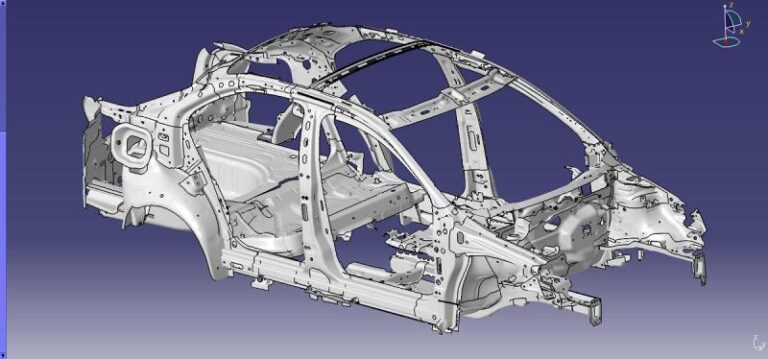

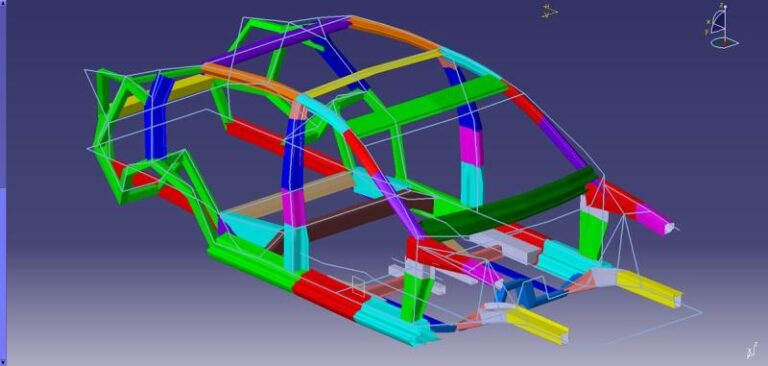

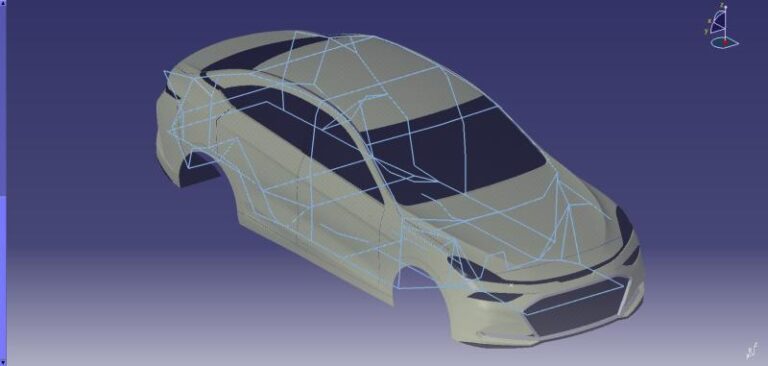

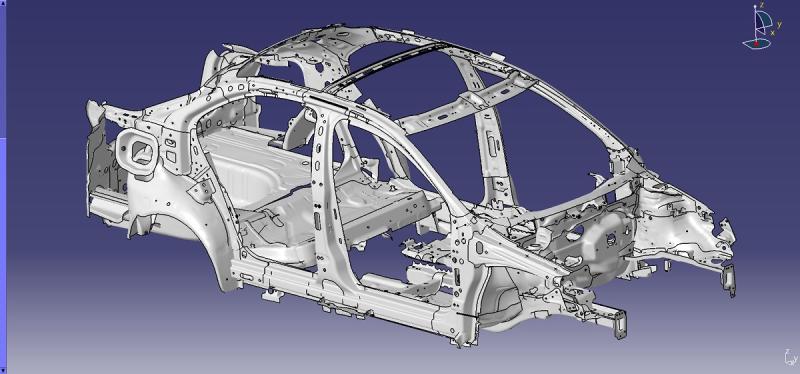

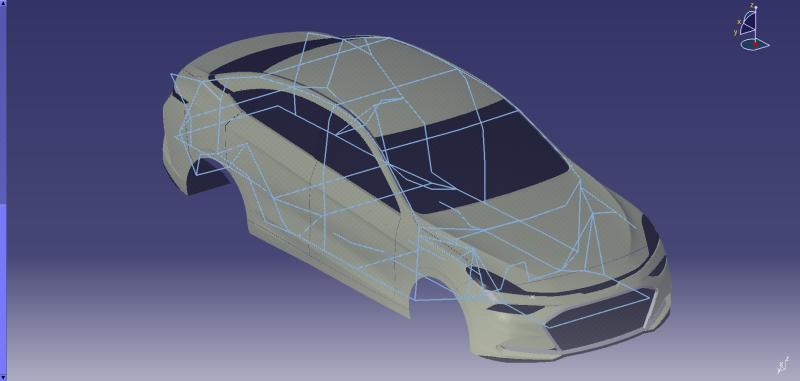

3D Modeler for International Platform JX10

In my role as a 3D Modeler, I contributed to the development of the JX10 platform, focusing on the following areas:

Vehicle Packaging: Ensuring optimal use of space within the vehicle.

Ergonomic Design and Simulation: Using advanced simulation techniques to enhance user comfort and safety.

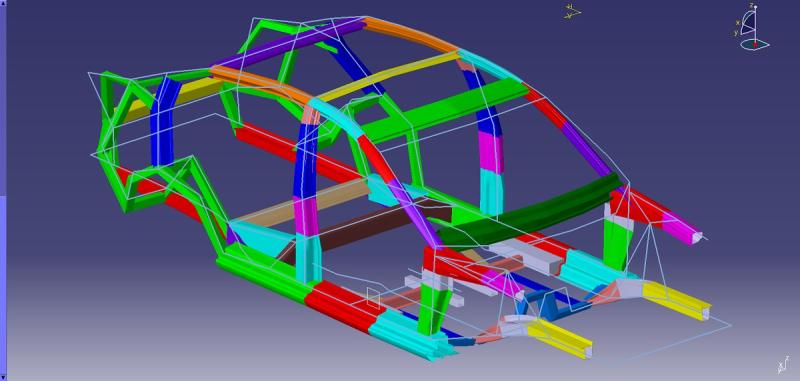

BIW (Body in White) Parametric Modeling: Utilizing scripting and formulas for efficient design.

Automotive Parts 3D Scanning: Applying reverse engineering techniques to create precise 3D models of automotive parts.

Chief Designer and Battery Packaging (First Electric Vehicle in Iran)

I led the design of the first full electric vehicle in Iran, focusing on battery packaging:

Designed a new generation of LI-ION battery packs, incorporating HVAC, NVH, and hazard limitations.

Modified and optimized the battery pack using MATLAB, resulting in a 20% weight reduction and 160 HP improvement.

Skills

- Inventor, 3D Printing, 3D Modeling, SolidWorks, CATIA

- Reverse Engineering, Computer-Aided Design (CAD), MATLAB

I developed CAD drawings to support prototype designs and ensured accurate documentation throughout the design process.

Achievements

Read and interpreted blueprints, technical drawings, schematics, and computer-generated reports.

Sketched designs and used CAD programs to create detailed specifications.

Developed communication documentation to convey key design aspects to clients effectively.

Mechanical Engineering Technician

2015 FEB -2019 NOV

IKCO – Iran Khodro

As a Mechanical Engineer at Iran Khodro Industrial Group (IKCO), a publicly traded company focused on manufacturing vehicles and parts, my primary role centered around the DENA vehicle and several other projects. I emphasized 3D modeling and 3D scanning, contributing to the design and development of vehicle components.

Skills

SolidWorks, Catia, Inventor

Automotive Engineering

Key Accomplishments

Organized and maintained a comprehensive data archive for engineering specifications, drawings, and documents, ensuring proper traceability through filing and indexing.

Forecasted project-related costs and tracked general project tasks, ensuring timely achievement of milestones.

Diagnosed mechanical problems and devised effective solutions, showcasing a proactive approach to problem-solving.

Collaborated with the quality office to provide technical validation for components, ensuring high standards of quality and compliance.

These experiences highlight my expertise in using key engineering tools, my ability to manage projects efficiently, and my commitment to high-quality standards in the automotive industry

Education

KIAU University

Bachelor of Mechanical Engineering Design

2011-2016

Employing CAD and CAM Software in the Design and Manufacturing Process of a Gearbox Featuring Helical Gears

Skills & language

Languages

English:Advanced

English:Advanced Italian:Intermediate

Italian:Intermediate Persian:Native

Persian:Native